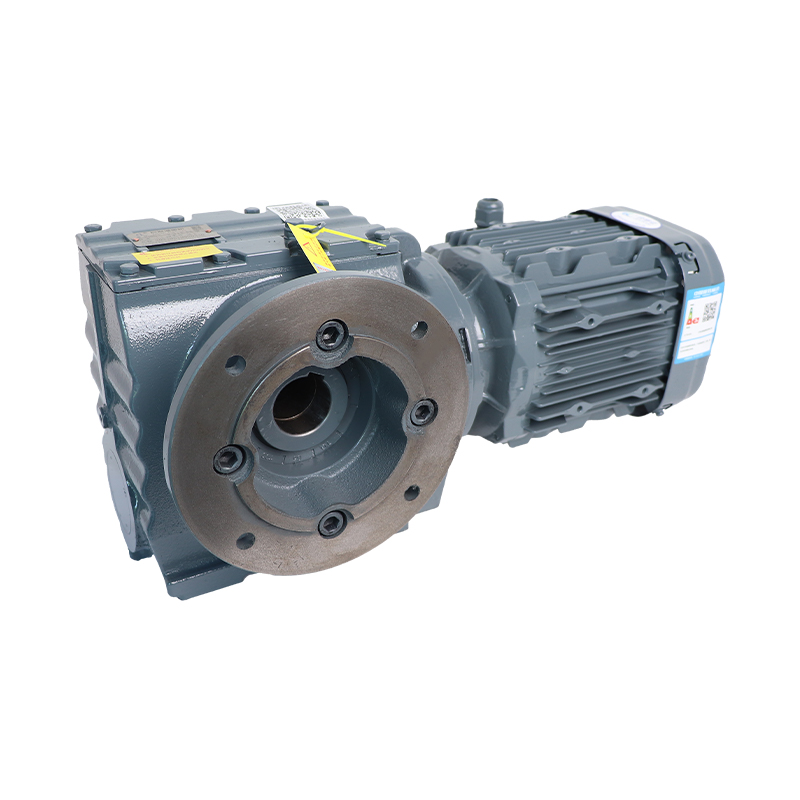

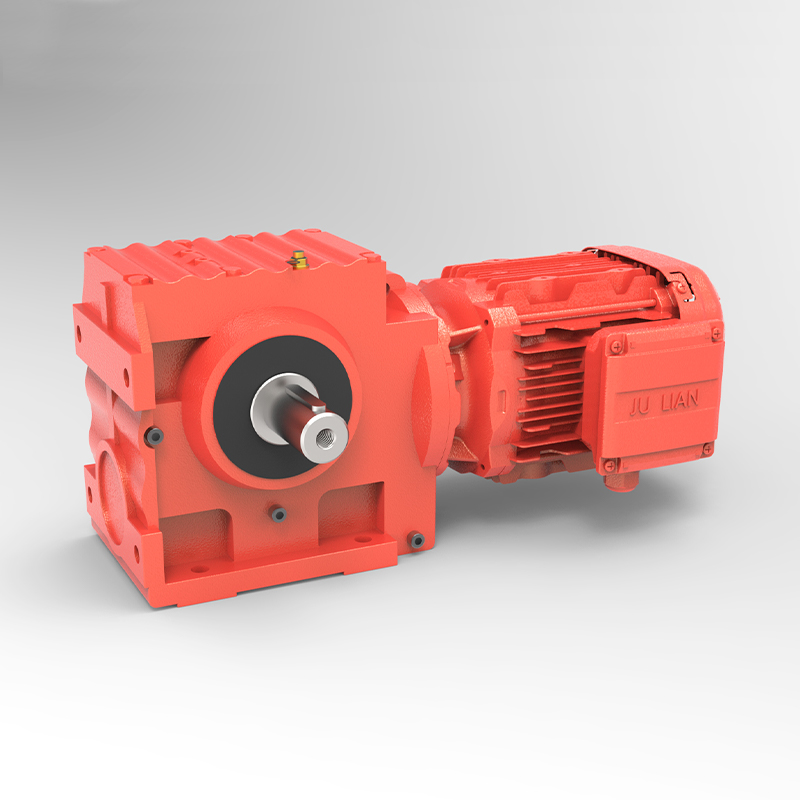

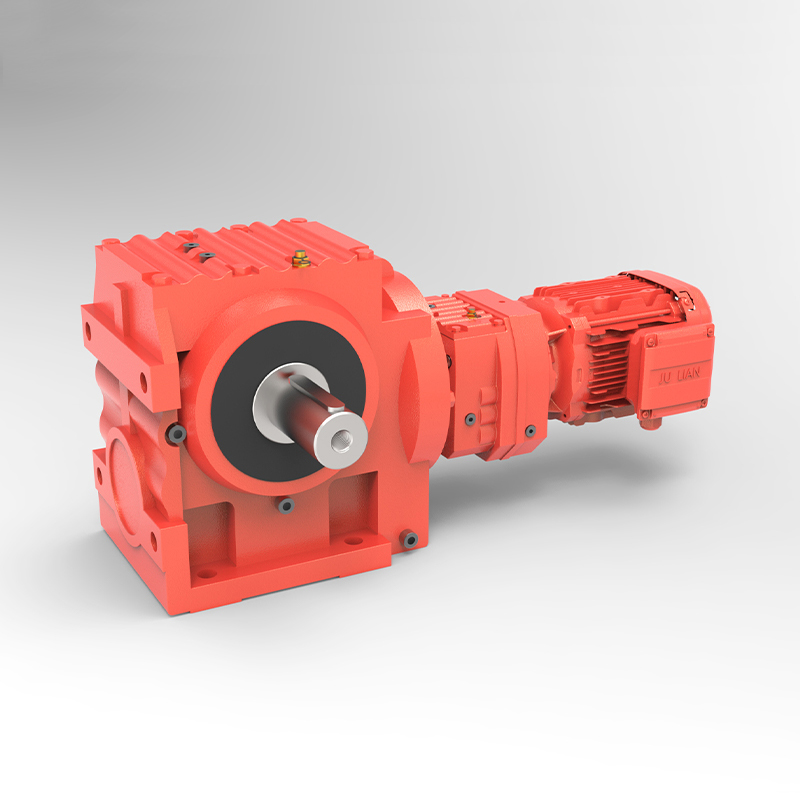

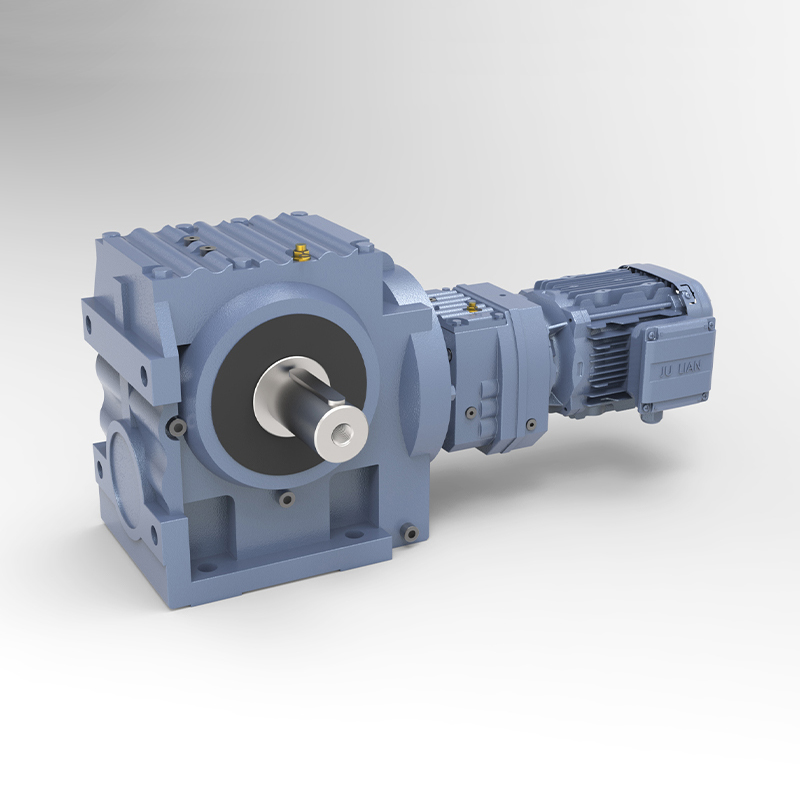

- Highly Standard Modular Designed: The products are easily connected with and driven by different types of motors or other kinds of input power. The same type of geared motor can be adapted to the optioned powers of motors.It is therefore easy to realize different solutions for varied requirements.

- Ratio: Featured many closely divided ratios and a wide range of them. Very big final ratios can be obtained through combined units to reach extremely low output speeds.

- Mounting Arrangement: No strict limitation to the mounting arrangement.

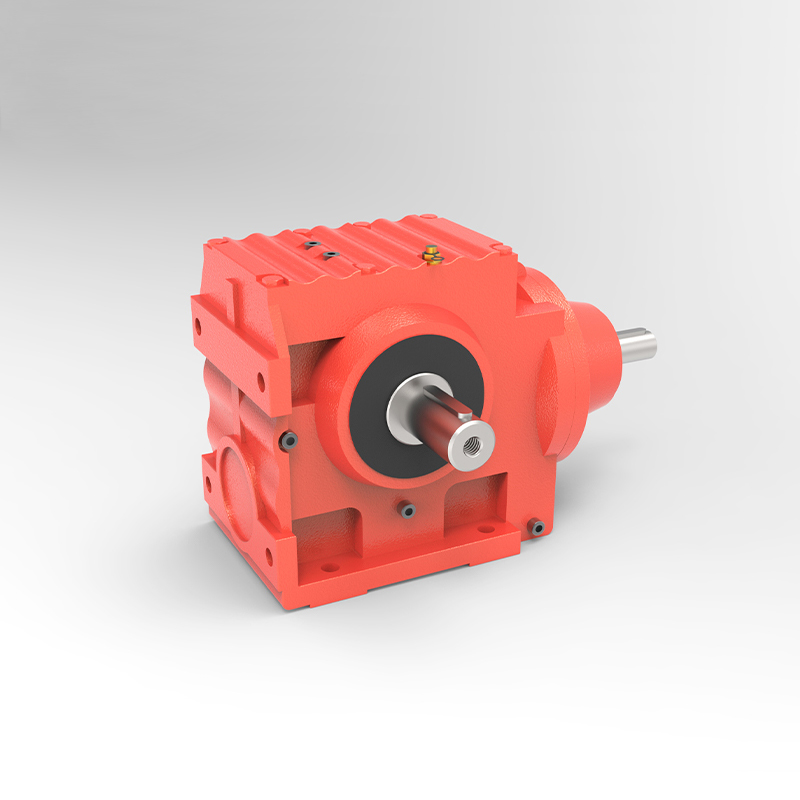

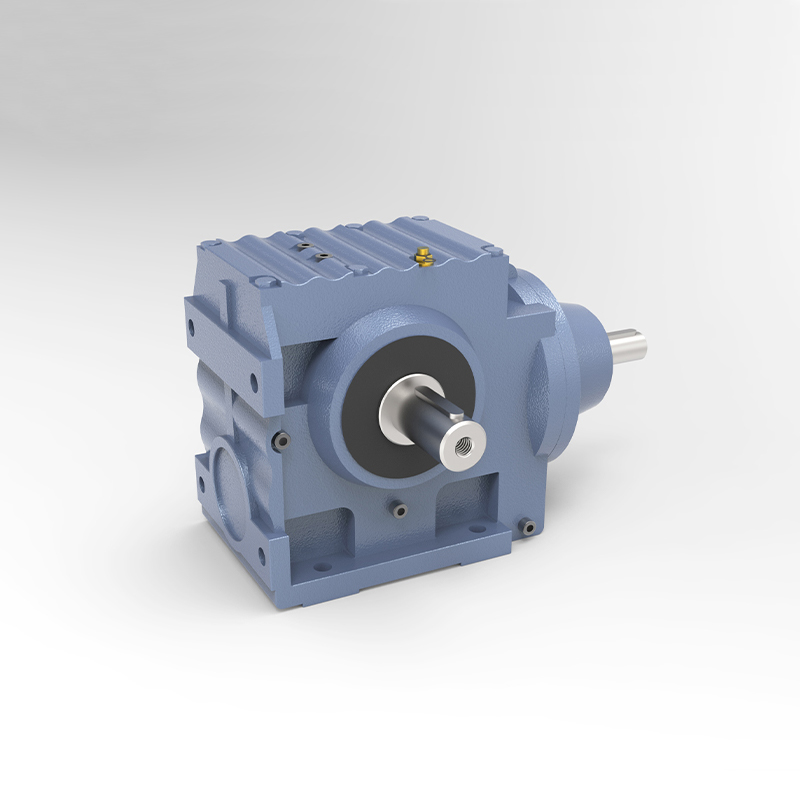

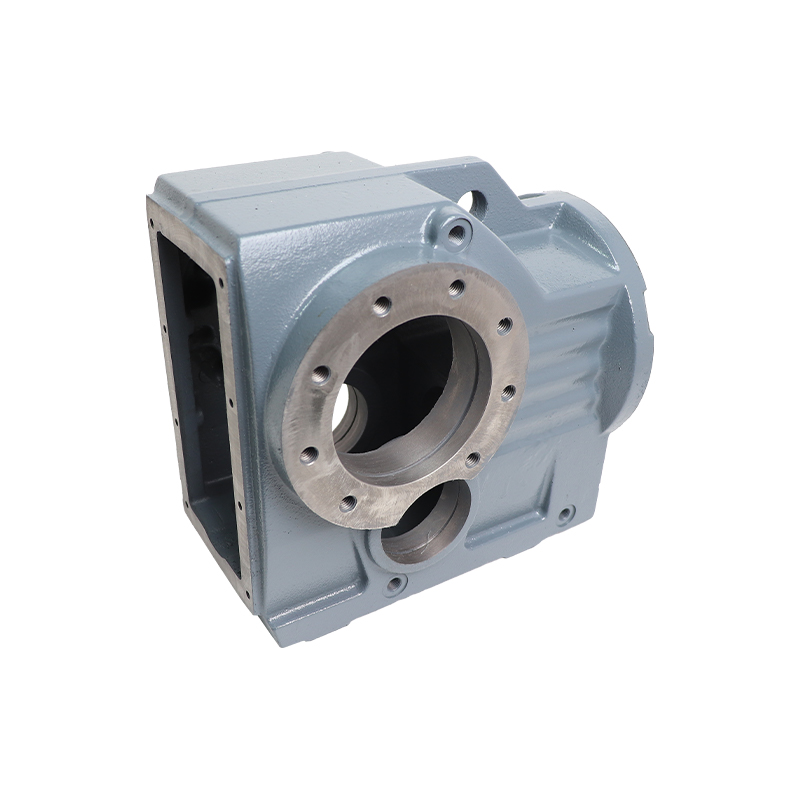

- High Strength, Compact Dimension: Housings are made of high strength cast iron. Gears and shaft gears are finished with a gas carburizing process and precise grounding to sequentially get high loading capacity of per certain volume.

- Long Service Life: Under the condition of accurately selecting type size and the normal maintenance and use, main components (except those easily disabled parts) can last as long as up to more than 25,000 hours. Easi-ly-disabled parts include lubricating oil, oil seals, and bearings.

- Low Noise: All key components are finished by precise machining, accurate assembly, and finally tested, and therefore, fairly low noise is reached.

- High Efficiency: The efficiency of the gear unit can reach 95%, and The efficiency of the worm gear unit can reach 89%.

- Large radial loading ability.

- Axial load ability of up to 5% of radial load.

-

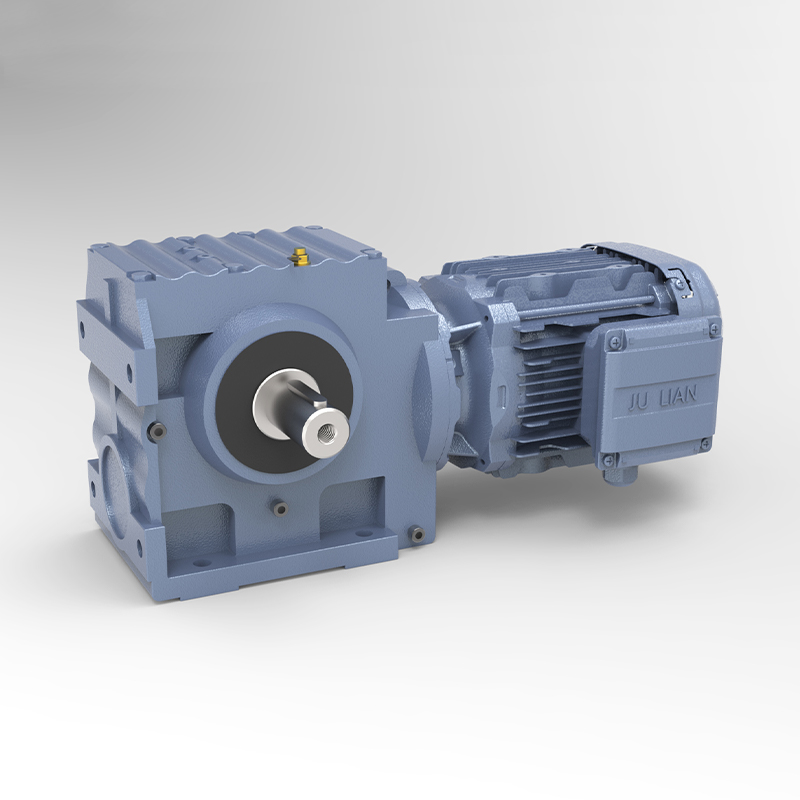

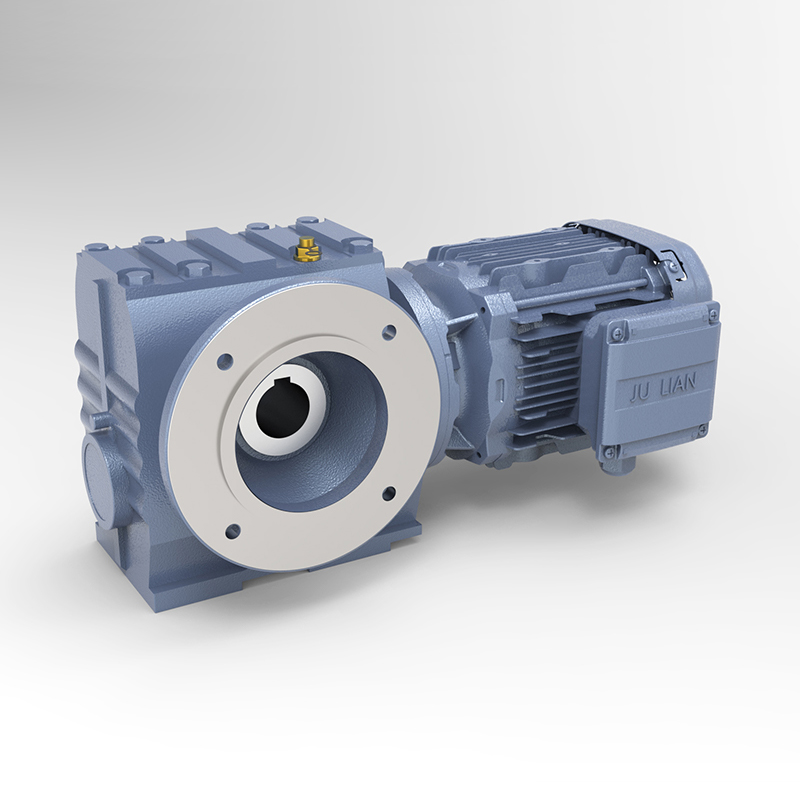

Foot-mounted helical-worm gear units with solid shaft.

Foot-mounted helical-worm gear units with solid shaft. -

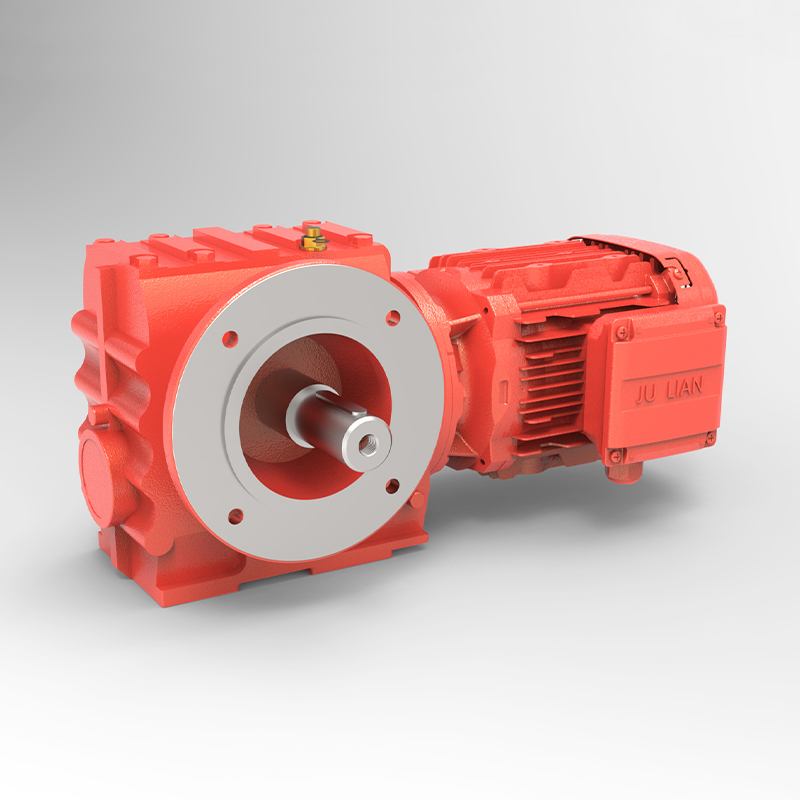

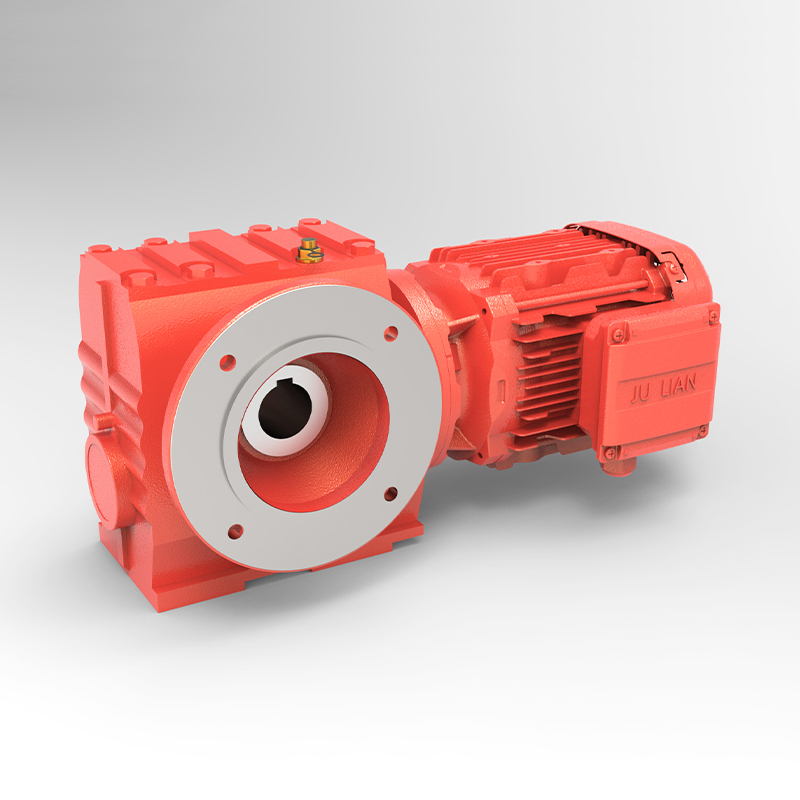

B5 flange mounted helical-worm gear units with solid shaft.

B5 flange mounted helical-worm gear units with solid shaft. -

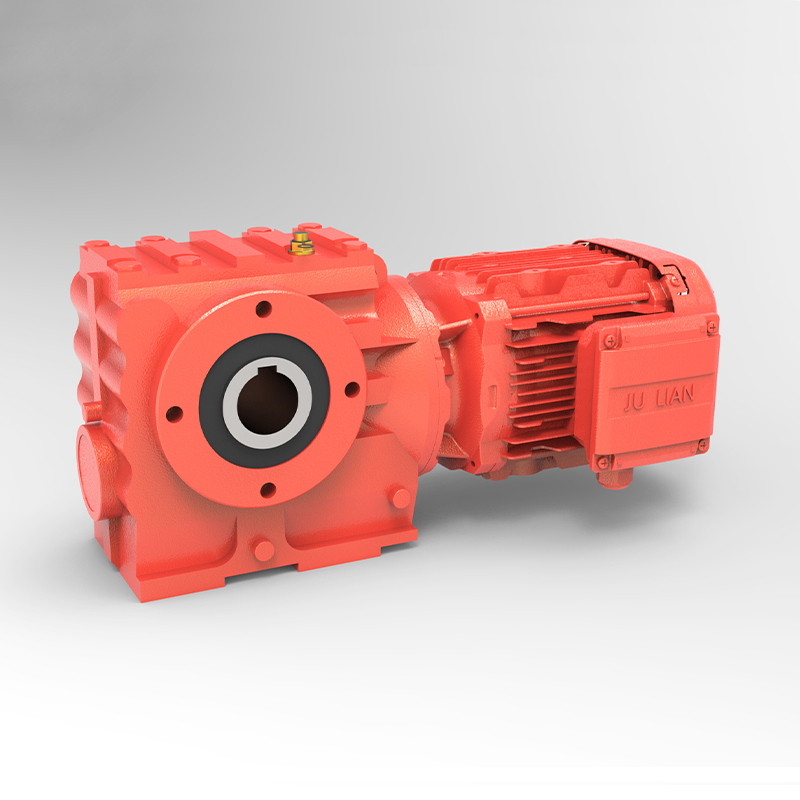

Helical-worm gear units with hollow shaft.

Helical-worm gear units with hollow shaft. -

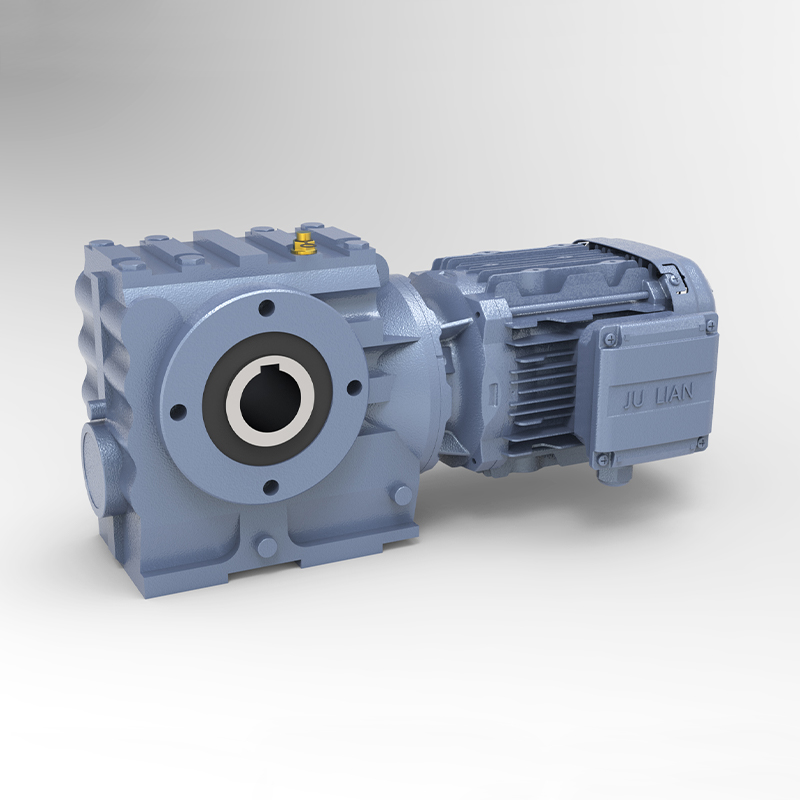

B5 flange mounted hlical-worm gear units with hollow shaft.

B5 flange mounted hlical-worm gear units with hollow shaft. -

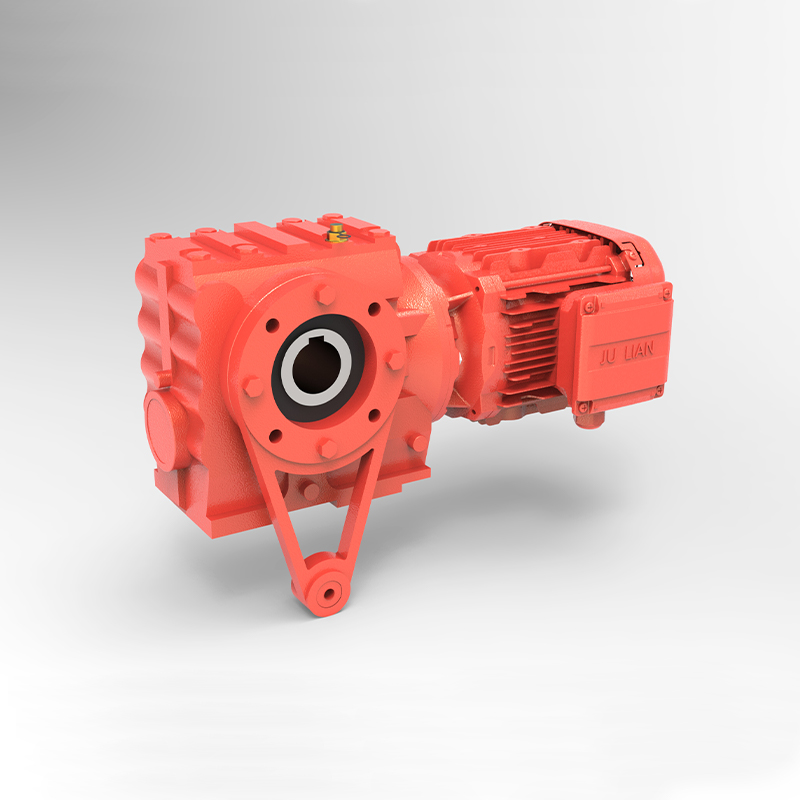

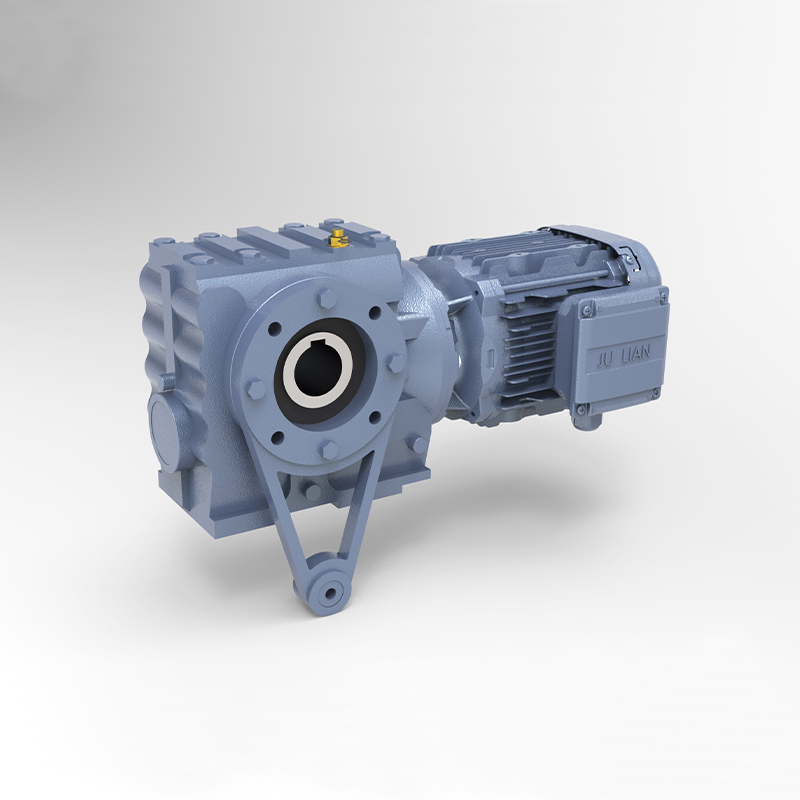

Torque-arm-mounted helical-worm gear units with hollow shaft.

Torque-arm-mounted helical-worm gear units with hollow shaft. -

Shaft input helical-worm gear units.

Shaft input helical-worm gear units. -

Combined types of series JS and series JR.

Combined types of series JS and series JR.

| Model |

Foot Mounting Dimensions |

Center Height |

Output Shaft Diameter |

Shaft Length |

Flat Key Width |

Flange Stop |

Flange Screw Hole Distance (mm) |

Flange Outer Diameter (mm) | Flange Mounting Holes (mm) |

Power(kw) |

Speed Ratio |

Maximum Permissible Torque |

| JS/SF37 | 63*90 | 80 | 20 | 40 | 6 | φ110/80 | φ130/100 | φ160/120 | 4-φ9/4-φ6.6 | 0.12~1.1 | 7.57~154.71 | 87 |

| JS/SF47 | 80*100 | 100 | 25 | 50 | 8 | φ110 | φ130 | φ160 | 4-φ9 | 0.12~1.5 | 8.04~201 | 170 |

| JS/SF57 | 100*110 | 112 | 30 | 60 | 8 | φ130 | φ165 | φ200 | 4-φ11 | 0.18~3 | 8.04~201 | 300 |

| JS/SF67 | 130*130 | 140 | 35 | 70 | 10 | φ130 | φ165 | φ200 | 4-φ11 | 0.25~5.5 | 7.79~217.41 | 520 |

| JS/SF77 | 135*150 | 180 | 45 | 90 | 14 | φ180 | φ215 | φ250 | 4-φ13.5 | 0.55~7.5 | 8.06~256.47 | 1220 |

| JS/SF87 | 180*200 | 225 | 60 | 120 | 18 | φ250 | φ300 | φ350 | 4-φ17.5 | 0.75~15 | 8.81~288 | 2300 |

| JS/SF97 | 235*250 | 280 | 70 | 140 | 20 | φ350 | φ400 | φ450 | 8-φ17.5 | 1.5~22 | 9.19~286.4 | 4000 |

| JS/SF100 | 570*300 | 390 | 90 | 170 | 25 | φ350 | φ400 | φ450 | 8-φ17.5 | 2.2~30 | 22.39~271.63 | 6500 |

| Model | Foot Mounting Dimensions (mm) |

Center Height (mm) |

Larger Hole Diameter (mm) | Larger Aperture Key Width (mm) | Smaller Hole Diameter (mm) | Smaller Aperture Key Width (mm) |

Power(kw) |

Speed Ratio |

Maximum Permissible Torque |

| JKF37 | / | 82 | 20 | 6 | / | / | 0.12~1.1 | 7.57~154.71 | 87 |

| JKF47 | 60*87 | 100 | 30 | 8 | 25 | 8 | 0.12~1.5 | 8.04~201 | 170 |

| JKF57 | 60*117 | 112 | 35 | 10 | 30 | 8 | 0.18~3 | 8.04~201 | 300 |

| JKF67 | 88*152 | 140 | 45 | 14 | 40 | 12 | 0.25~5.5 | 7.79~217.41 | 520 |

| JKF77 | 102*170 | 180 | 60 | 18 | 50 | 14 | 0.55~7.5 | 8.06~256.47 | 1220 |

| JKF87 | 118*225 | 225 | 70 | 20 | 60 | 18 | 0.75~15 | 8.81~288 | 2300 |

| JKF97 | 160*248 | 280 | 90 | 25 | 70 | 20 | 1.5~22 | 9.19~286.4 | 4000 |

| JKF107 | / | 340 | 100 | 28 | 90 | 20 | 2.2~30 | 22.39~271.63 | 6500 |

|

|

|

|

|

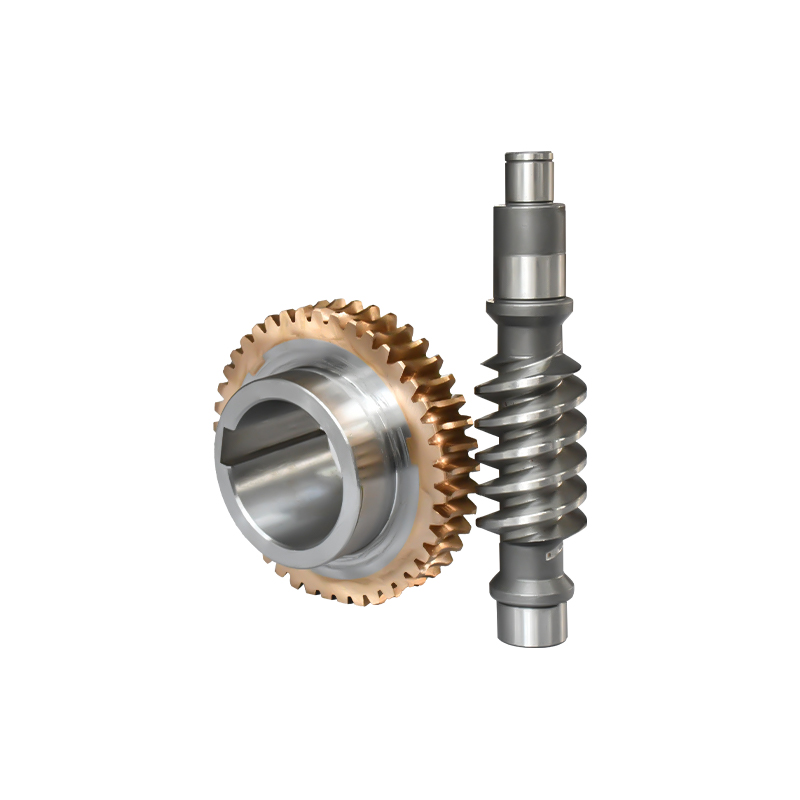

Precision Gear Made of 20CrMnTi gear steel, gas carburizing and quenching fine grinding process, gear grinding accuracy of level 6, strong wear resistance, high hardness, high load-bearing capacity per unit volume |

Gear shaft Made of 20CrMnTi gear steel, quenched and precision ground, with strong bearing capacity |

Turbine Made of tin bronze 12-2 material, high hardness, wear-resistant and corrosion-resistant. |

Cabinet HT200 gray cast, high-strength cast iron, clean and burr-free inner cavity |

|

|

|

|

|

Output shaft Made of 40CR material, tempered and heat treated, with high hardness and stronger bearing capacity |

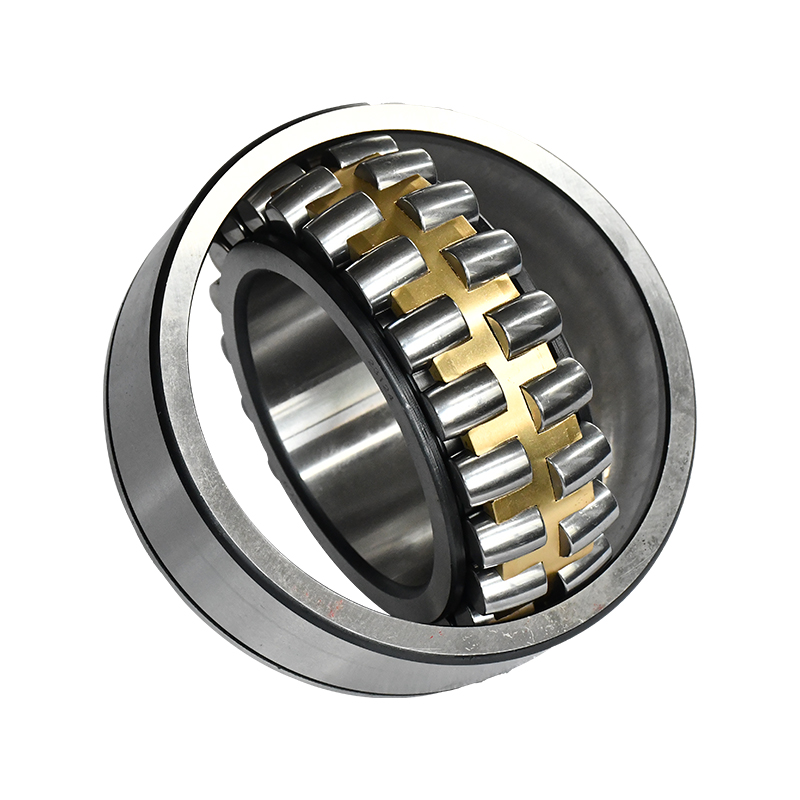

Bearings The brands are Luozhou or Wafangdian bearings, which have the characteristics of low noise, low friction, good load, and fast speed. |

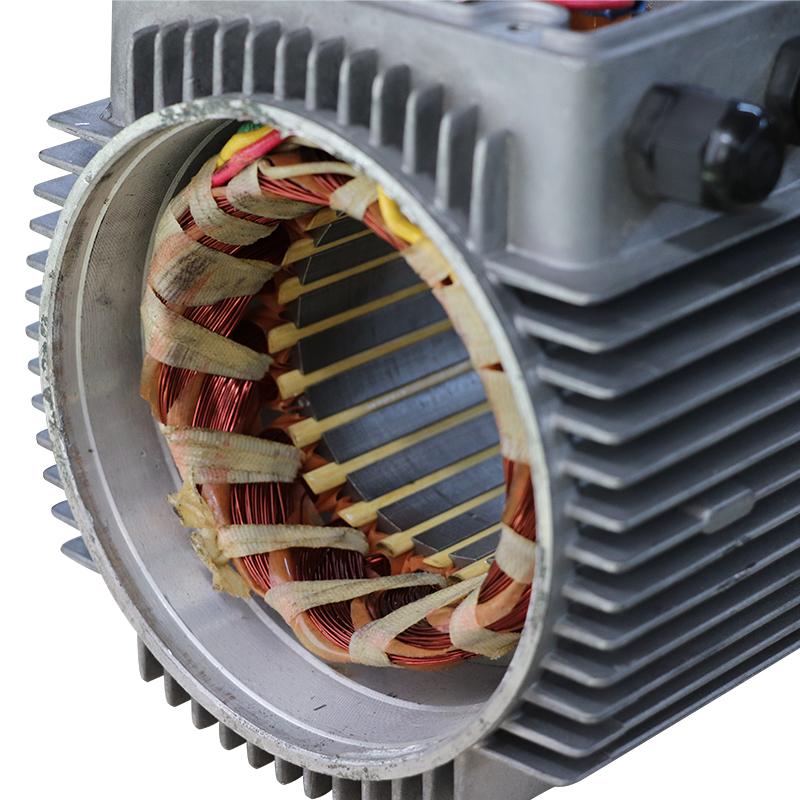

Motor Made of pure copper coil, silicon steel sheet cold rolled 800, low loss, high-temperature resistance, small temperature rise, strong power, a multi-layer primer layer of high-density molecular insulating paint, effective insulation and dustproof, strong durability and long life long |

|

- MOQ: 1 set

- Packing method: Polywood

- Delivery lead time: 7-25 days

- Payment terms: FOB, CIF, CFR

- Payment method: T/T or L/C

- Shipping port: Shanghai or Ningbo

Warranty period 12 months. Fueling grade CKC220# medium load gear oil.

EN

EN  English

English Español

Español русский

русский